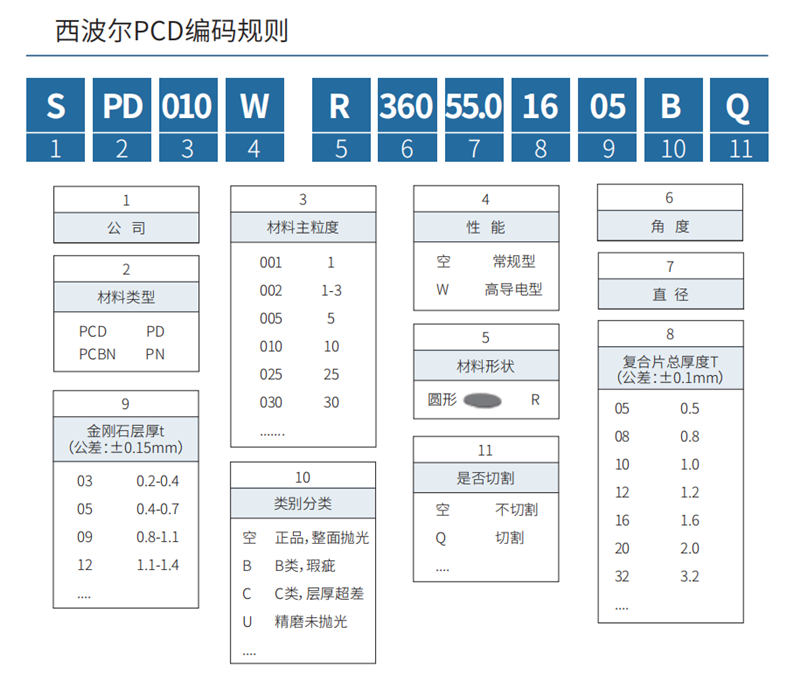

Products

PCD composite sheet

Polycrystalline diamond compact blanks (PCD for short) is a composite super hard material made of a mixed diamond powder and a cemented carbide matrix sintered under high temperature and pressure.The diamond crystals in the diamond layer of PCD are arranged in a disordered manner, isotropic, and have no cleavage surface. They have the high hardness, high wear resistance and high thermal conductivity of diamond; the cemented carbide layer as the substrate has high impact toughness and weldability.Therefore, PCD is particularly suitable for cutting tools of non-ferrous metals and non-metallic materials and supporting wear-resistant parts of various instruments and equipment.

Description

Product performance

PCD composite sheet model and its wear resistance and conductivity

Product model

Performance ranking of wear-resistant and conductive PCD

SPD002

Wear resistance of wear-resistant PCD:

SPD030>SPD010>SPD005>SPD002>

SPD025W>SPD010W>SPD010BW

Conductivity sorting of conductive PCD:

SPD010BW>SPD010W>SPD025W>

SPD002>SPD005

Remarks: Products of different granularity can be customized according to customer needs

SPD005

SPD010

SPD030

SPD010W

SPD010BW

SPD025W

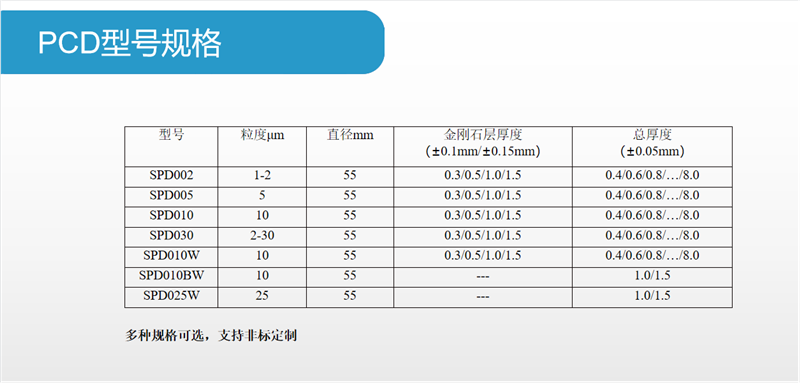

Product model

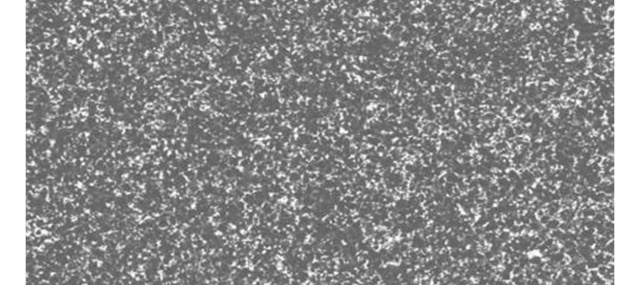

(1)Model:SPD002

Model SPD002 Particle size 2μm Features Particle size is fine.It has high toughness, good wear resistance and electrical processability. Application Used in the 3C industry, low-silicon aluminum alloy processing (electronic products, computers, mobile phones, etc.).

Electron microscope diagram

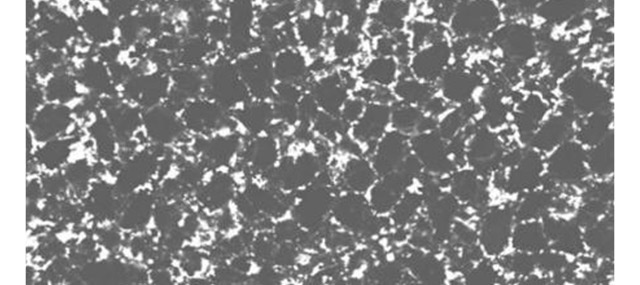

(2) Model:SPD005

Model SPD005 Particle size 5μm Features Particle size is fine.It has good wear resistance and high impact resistance. Application It is suitable for the 3C industry and the processing of copper, aluminum, wood, plastic, glass fiber and other materials.

Electron microscope diagram

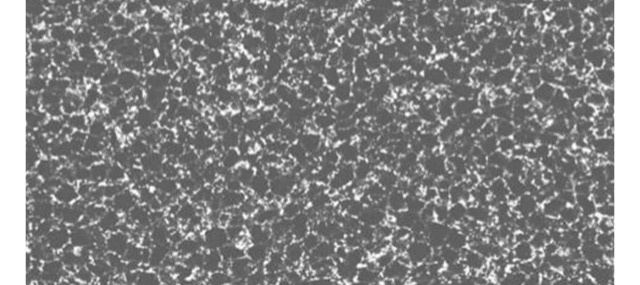

(3) Model:SPD010

Model SPD010 Particle size 10μm Features Medium particle size.It has good wear resistance and impact resistance. Application It is suitable for the processing of copper, aluminum, aviation composite materials, wood, plastics and other materials, and has a wide application range.

Electron microscope diagram

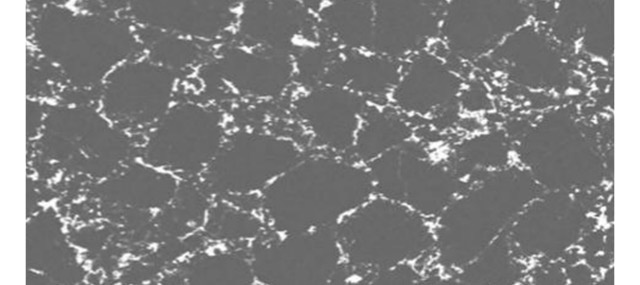

(4) Model:SPD010W

Model SPD010W Particle size 10μm Features Medium particle size.It has excellent electrical processing performance and impact resistance, as well as good wear resistance. Application It is suitable for various PCD tools manufactured by electric machining technology, as well as PCD tools that require high wear resistance and at the same time have higher impact resistance requirements.It is especially suitable for milling cutters, drill bits, saw blades, etc. for the processing of composite materials, wood, plastics, aluminum, copper and other materials.

Electron microscope diagram

(5) Model:SPD030

Model SPD030 Particle size 2-30μm Features Mixed particle size, with high wear resistance, good impact resistance and thermal stability. Application It is suitable for the processing of high-hardness non-ferrous metal alloys (such as high-silicon aluminum alloys, cemented carbide), graphite, glass fiber, ceramics, composite flooring and other materials.

Electron microscope diagram

(6) Model:SPD025W

Model SPD025W Particle size 25μm Features It has good wear resistance, electrical conductivity, and high impact resistance. Application It is suitable for PCD tools manufactured by electric processing technology, such as wood, aluminum saws and composite materials.

Electron microscope diagram

Processing case

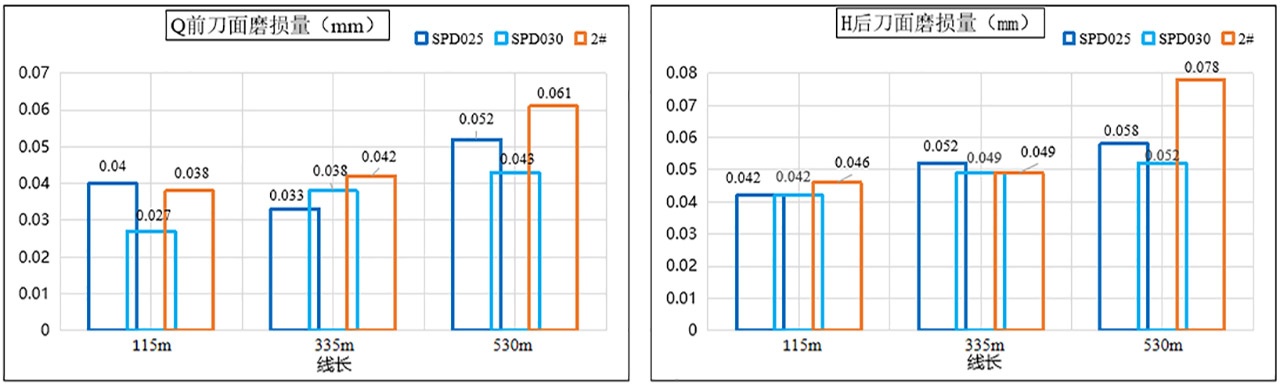

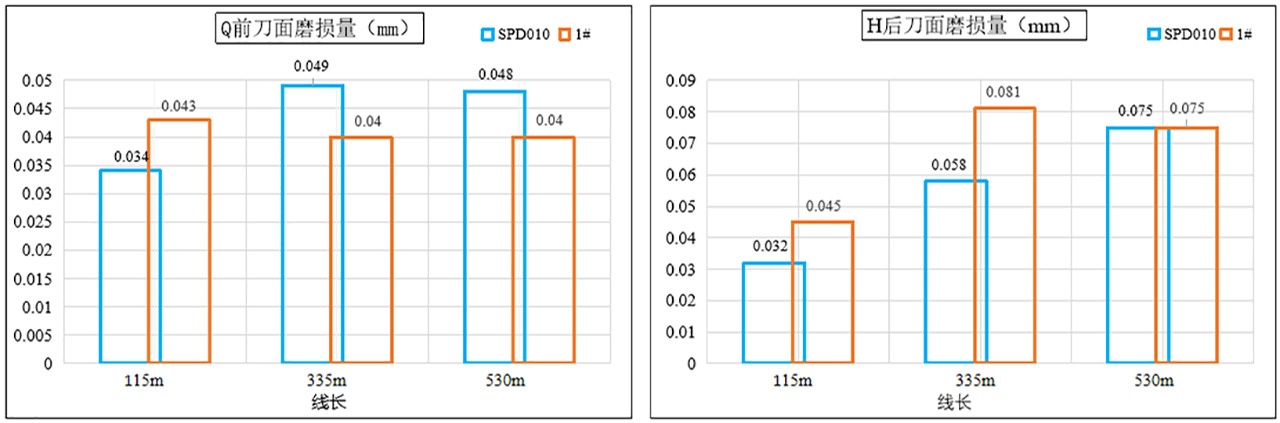

| Processing test case 1 | ||||||

| Processing object | Manufacturer | Material | Particle size (μm) | Cutting depth (mm) | Cutting speed (m/min) | Feed per turn (mm/r) |

| Cemented carbide GU20 | A foreign company | 1# | 10 | 0.1mm | 50 | 0.03 |

| Langfang Supower | SPD010 | 10 | 0.1mm | 50 | 0.03 | |

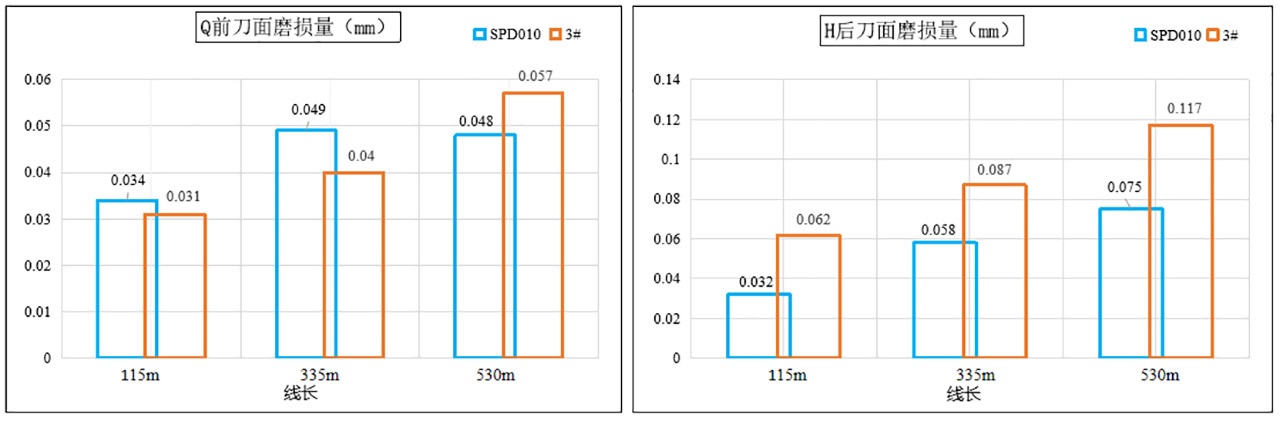

| Processing test case 2 | ||||||

| Processing object | Manufacturer | Material | Particle size (μm) | Cutting depth (mm) | Cutting speed (m/min) | Feed per turn (mm/r) |

| Cemented carbide GU20 | A foreign company | 3# | 10 | 0.1mm | 50 | 0.03 |

| Langfang Supower | SPD010 | 10 | 0.1mm | 50 | 0.03 | |

| Processing test case 3 | ||||||

| Processing object | Manufacturer | Material | Particle size (μm) | Cutting depth (mm) | Cutting speed (m/min) | Feed per turn (mm/r) |

| Cemented carbide GU20 | Langfang Supower | SPD025 | 25 | 0.1mm | 50 | 0.03 |

| Langfang Supower | SPD030 | 30 | 0.1mm | 50 | 0.03 | |

| A foreign company | 2# | 30 | 0.1mm | 50 | 0.03 | |